The benefits of controlled oxygen with the Visio range

Oxygen, although often feared by winemakers, can become a powerful ally when properly controlled. Here are just some of the benefits that controlled oxygenation brings to your winemaking process:

- Secure fermentations: Ensure complete fermentation and avoid reduction problems.

- Softening of tannins: Produce roundness wines, more mouthfeel.

- Prevent reduction: Avoid taste alterations due to poor oxygen management.

- Shorten aging time: Speed up the process while preserving quality.

-

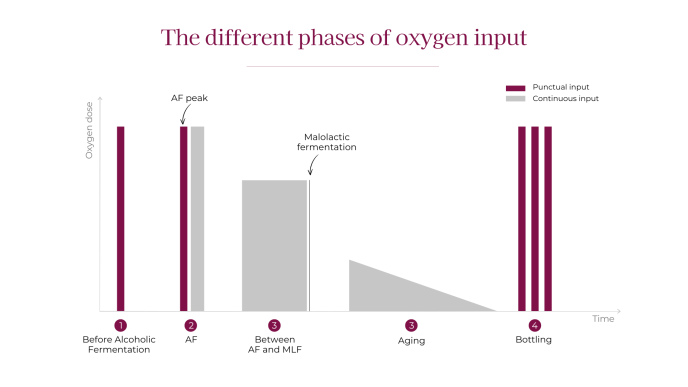

Before Alcoholic Fermentation (AF)

With the O2CM (Controlled Oxygenation of Musts) function, inject the right dose of oxygen to reduce the oxidizability of white and rosé musts while preserving aromas. Vivelys' Cilyo® tool determines the ideal dose of oxygen to inject, guaranteeing safe application.

-

AF peak

The Visio's "Cliquage" function enables efficient oxygenation of yeast at the optimum rate and dose. This improves alcohol tolerance and nitrogen nutrient absorption, securing the end of fermentation and avoiding reduction.

-

Between AF and MLF

The Visio's "micro-Ox" function provides oxygen during and after alcoholic fermentation at a low, continuous flow rate. This improves the suppleness of the tannins, adds roundness to the wine and reduces greenness. To find out more about securing alcoholic fermentations, visit our other article: "Oxygen in wines to secure your AF".

-

Bottling preparation

"Micro-cliquages" before bottling avoids reducing returns, ensuring a stable wine ready for drinking.

Choosing between oxygenation and micro-oxygenation

Oxygenation (or macro-oxygenation): Introduces a large quantity of oxygen on a punctual basis, measured in mg/L. Used to oxygenate yeast during AF, or to lift a major reduction before bottling.

Micro-oxygenation: Introduces small quantities of oxygen on a continuous basis, measured in ml/L/month. It is used to enhance the structure and body of the wine, resulting in more complex, well-balanced wines. To find out more about the effects and benefits of micro-oxygenation, visit our article here.

The Visio range offers 45 integrated programs, allowing you to choose between these two methods.

Why use Visio to control oxygen?

- Preservation of a clean wine: A controlled dose of oxygen and good yeast nutrition guarantee complete fermentation, resulting in a clean, precise aromatic profile.

- Soft, round wines: In red wines, tannins are softened, and the RedOx balance and color quality are stabilized.

- Safe input: The system detects leaks, empty bottles or other problems, and the input stops automatically at the end of the chosen program, guaranteeing maximum safety.

By controlling oxygen with Visio range, you can transform a potentially problematic element into a powerful ally for winemaking. With over 45 integrated programs and cutting-edge technology, Visio guides you through every type of wine, ensuring consistently high quality. Embrace oxygen control and discover how it can revolutionize your winemaking process.